| Availability: | |

|---|---|

| Quantity: | |

TCS37-160/40A

TERTRON

Description

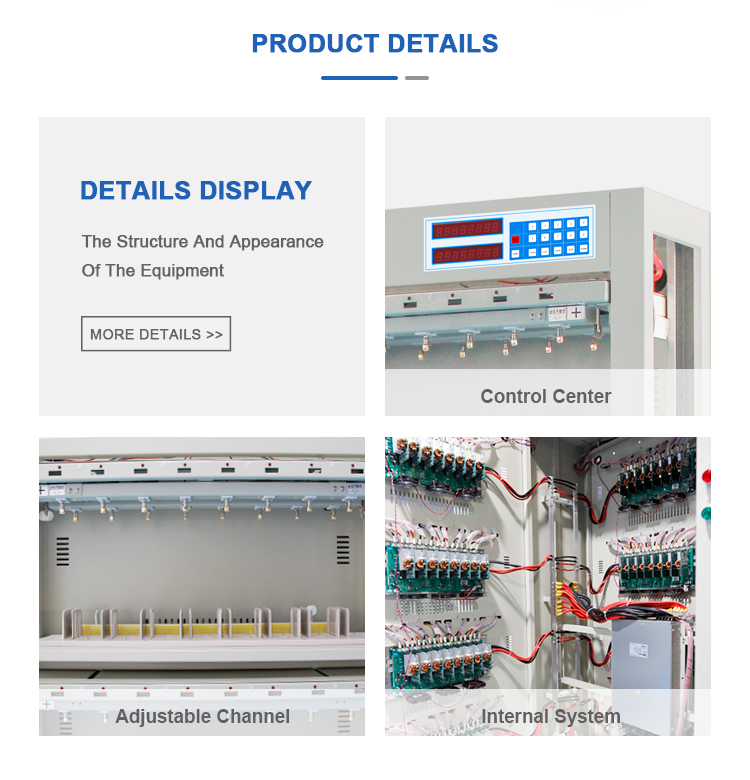

TCS37-160/40A Pressure-type Prismatic Aluminum Shell Battery Capacity Grading Machine, a cutting-edge lithium-ion battery capacity tester designed for precision, efficiency, and durability. As a seasoned expert in battery equipment, we understand the critical importance of precision, efficiency, and adaptability in battery manufacturing processes. Our grading machine is meticulously engineered to deliver unparalleled accuracy and performance in the grading of prismatic aluminum shell battery.

Key Features

- Innovative Pressure-based Grading Mechanism: Setting a new standard in battery grading technology, our machine utilizes a pressure-based grading mechanism specifically tailored for prismatic batteries housed in aluminum shells. This innovative approach ensures precise and consistent grading results, enhancing overall battery quality and performance.

- Customizable Grading Parameters: Designed to accommodate the unique characteristics of prismatic aluminum shell batteries, our grading machine offers customizable grading parameters. Operators have the flexibility to adjust parameters such as pressure levels, cutoff voltage, and discharge characteristics to tailor the grading process to specific battery chemistries and performance specifications.

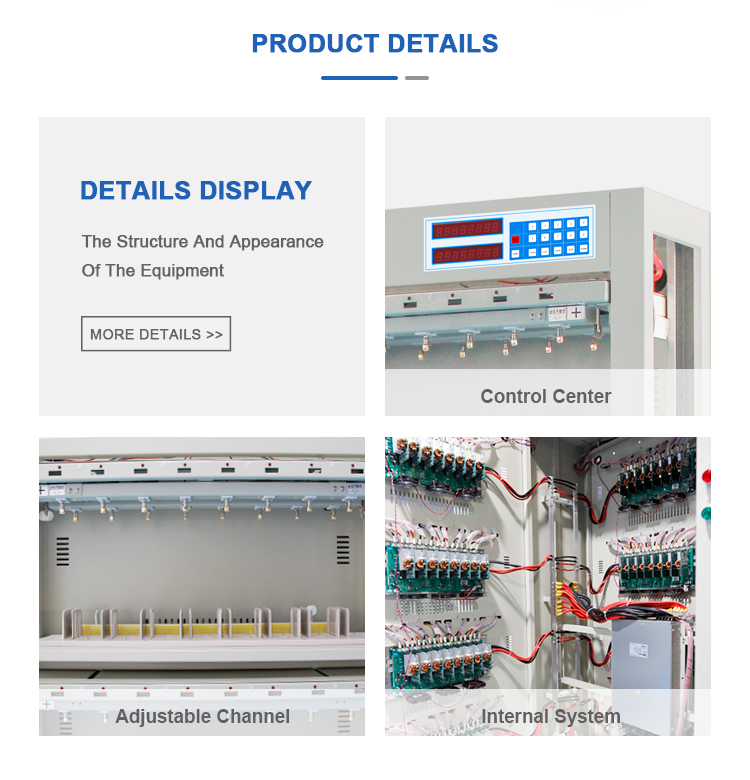

- Automated Grading Process: Engineered for seamless integration into production lines, our grading machine features an automated grading process. With advanced robotics and conveyor systems, batteries are efficiently handled and graded according to predefined criteria, minimizing manual intervention and maximizing throughput.

- High Precision Measurement and Analysis: Equipped with state-of-the-art sensors and measurement tools, our grading machine ensures precise and reliable assessment of battery performance metrics. Real-time data analysis provides valuable insights into capacity, voltage, and internal resistance, enabling accurate grading and quality control.

- Safety and Reliability: Committed to safety and reliability, our grading machine is built with robust materials and incorporates comprehensive safety features. Emergency stop buttons, safety interlocks, and protective enclosures ensure operator safety and prevent accidents, allowing for smooth and uninterrupted operation.

- User-friendly Interface: Designed for ease of use, our grading machine features an intuitive user interface that simplifies operation and monitoring. Operators can easily adjust settings, monitor grading processes, and access data logging and reporting features with minimal training, optimizing efficiency and productivity.

- Quality Assurance and Sorting: With a focus on quality assurance, our grading machine categorizes batteries into different grades or classes based on their performance metrics. This ensures that only batteries meeting stringent quality standards are selected for further use, enhancing overall product reliability and customer satisfaction.

Fixture Form Pneumatic clamping /manual quick clamping |  Fixture type Electric clamp opening, enhanced flat head clamp |  Fixture spacing 81MM |  Support battery Prismatic battery |  Dimensions length*width*height 1880*1008*2033(MM) |

Product Parameters

| Structure Of Equipment | |||

| Device Channel | 160 channels | Overall Dimension | Width 1880mm× Depth 1008mm× Height 2033mm |

| Fixture Form | Electric clamp opening, enhanced flat head clamp | ||

| Fixture Spacing | 81MM | ||

Support Battery Specifications | 1. Battery compatible length 90-210mm 2. Thickness 16-70mm 3. Height 80-230mm 4. Battery tabs 40-150mm | ||

Working Power Supply | Three-phase five-wire system AC380V±10%,50HZ | ||

| Power Factor | 0.99 @220V AC, Fully loaded, power grid THDu≤2% | ||

| Ac Current Distortion Rate | <5% @220V AC, Fully loaded, power grid THDu≤2% | ||

Working Power Consumption | ≤28 KW | Heat-Dissipating Method | Air cooling |

| Charging Efficiency Of Whole Machine | Charge≥80%; discharge≥70% | ||

| Work Environment | Indoors, temperature is 10-30℃ under air convection | ||

| Channel Parameters | |||

Voltage Measurement Range | DC 0~5V | Battery Voltage Range | Charging DC0~4.5V; discharging DC 4.5~2V |

Constant Voltage Range | DC 2~4.5V | Voltage Accuracy | ±(0.5%o reading +0.5% full scale) |

Voltage Resolution | 0.1mV | Voltage Stability | ≤(±1mV) |

Current Range | Charge DC100mA~ 40A;Discharge DC 100mA~40A | ||

Current Accuracy | ±(0.5% Reading+0.5% Full Degre) | Current Steady Reading | ≤(±1mA) |

| Software Function | |||

Control Method | Computer Control Equipment Work, whole cabinet control/single board startup/single point startup, with scanning system | ||

Communication Method | 485 serial port communication (baud rate 57600)/TCP communication/chart | ||

Process Settings | Up to 32 work steps and 256 cycles can be set, with the function of nested loops | ||

Charging Mode | Constant Current, Constant Voltage, Constant Current and Constant Voltage | ||

Charging Cut-off Conditions | Constant, current, constant, voltage, -△V | ||

Discharge Mode | Voltage, current, time, capacity | ||

Discharge Cut-off Conditions | Voltage, time, capacity | ||

Time Limit | 0~ 30000 minutes/work step, time unit: min | ||

Time Accuracy | ≤±1%0 | ||

Sampling Inspection Cycle | 1s-60s optional | ||

Description

TCS37-160/40A Pressure-type Prismatic Aluminum Shell Battery Capacity Grading Machine, a cutting-edge lithium-ion battery capacity tester designed for precision, efficiency, and durability. As a seasoned expert in battery equipment, we understand the critical importance of precision, efficiency, and adaptability in battery manufacturing processes. Our grading machine is meticulously engineered to deliver unparalleled accuracy and performance in the grading of prismatic aluminum shell battery.

Key Features

- Innovative Pressure-based Grading Mechanism: Setting a new standard in battery grading technology, our machine utilizes a pressure-based grading mechanism specifically tailored for prismatic batteries housed in aluminum shells. This innovative approach ensures precise and consistent grading results, enhancing overall battery quality and performance.

- Customizable Grading Parameters: Designed to accommodate the unique characteristics of prismatic aluminum shell batteries, our grading machine offers customizable grading parameters. Operators have the flexibility to adjust parameters such as pressure levels, cutoff voltage, and discharge characteristics to tailor the grading process to specific battery chemistries and performance specifications.

- Automated Grading Process: Engineered for seamless integration into production lines, our grading machine features an automated grading process. With advanced robotics and conveyor systems, batteries are efficiently handled and graded according to predefined criteria, minimizing manual intervention and maximizing throughput.

- High Precision Measurement and Analysis: Equipped with state-of-the-art sensors and measurement tools, our grading machine ensures precise and reliable assessment of battery performance metrics. Real-time data analysis provides valuable insights into capacity, voltage, and internal resistance, enabling accurate grading and quality control.

- Safety and Reliability: Committed to safety and reliability, our grading machine is built with robust materials and incorporates comprehensive safety features. Emergency stop buttons, safety interlocks, and protective enclosures ensure operator safety and prevent accidents, allowing for smooth and uninterrupted operation.

- User-friendly Interface: Designed for ease of use, our grading machine features an intuitive user interface that simplifies operation and monitoring. Operators can easily adjust settings, monitor grading processes, and access data logging and reporting features with minimal training, optimizing efficiency and productivity.

- Quality Assurance and Sorting: With a focus on quality assurance, our grading machine categorizes batteries into different grades or classes based on their performance metrics. This ensures that only batteries meeting stringent quality standards are selected for further use, enhancing overall product reliability and customer satisfaction.

Fixture Form Pneumatic clamping /manual quick clamping |  Fixture type Electric clamp opening, enhanced flat head clamp |  Fixture spacing 81MM |  Support battery Prismatic battery |  Dimensions length*width*height 1880*1008*2033(MM) |

Product Parameters

| Structure Of Equipment | |||

| Device Channel | 160 channels | Overall Dimension | Width 1880mm× Depth 1008mm× Height 2033mm |

| Fixture Form | Electric clamp opening, enhanced flat head clamp | ||

| Fixture Spacing | 81MM | ||

Support Battery Specifications | 1. Battery compatible length 90-210mm 2. Thickness 16-70mm 3. Height 80-230mm 4. Battery tabs 40-150mm | ||

Working Power Supply | Three-phase five-wire system AC380V±10%,50HZ | ||

| Power Factor | 0.99 @220V AC, Fully loaded, power grid THDu≤2% | ||

| Ac Current Distortion Rate | <5% @220V AC, Fully loaded, power grid THDu≤2% | ||

Working Power Consumption | ≤28 KW | Heat-Dissipating Method | Air cooling |

| Charging Efficiency Of Whole Machine | Charge≥80%; discharge≥70% | ||

| Work Environment | Indoors, temperature is 10-30℃ under air convection | ||

| Channel Parameters | |||

Voltage Measurement Range | DC 0~5V | Battery Voltage Range | Charging DC0~4.5V; discharging DC 4.5~2V |

Constant Voltage Range | DC 2~4.5V | Voltage Accuracy | ±(0.5%o reading +0.5% full scale) |

Voltage Resolution | 0.1mV | Voltage Stability | ≤(±1mV) |

Current Range | Charge DC100mA~ 40A;Discharge DC 100mA~40A | ||

Current Accuracy | ±(0.5% Reading+0.5% Full Degre) | Current Steady Reading | ≤(±1mA) |

| Software Function | |||

Control Method | Computer Control Equipment Work, whole cabinet control/single board startup/single point startup, with scanning system | ||

Communication Method | 485 serial port communication (baud rate 57600)/TCP communication/chart | ||

Process Settings | Up to 32 work steps and 256 cycles can be set, with the function of nested loops | ||

Charging Mode | Constant Current, Constant Voltage, Constant Current and Constant Voltage | ||

Charging Cut-off Conditions | Constant, current, constant, voltage, -△V | ||

Discharge Mode | Voltage, current, time, capacity | ||

Discharge Cut-off Conditions | Voltage, time, capacity | ||

Time Limit | 0~ 30000 minutes/work step, time unit: min | ||

Time Accuracy | ≤±1%0 | ||

Sampling Inspection Cycle | 1s-60s optional | ||