Views: 0 Author: Site Editor Publish Time: 2025-02-05 Origin: Site

In today’s rapidly advancing technological landscape, the demand for efficient and high-quality battery production lines has reached unprecedented levels. Batteries are the power source behind electric vehicles, renewable energy systems, consumer electronics, and countless industrial devices. As global industries move toward electrification and sustainability, the ability to manufacture batteries efficiently and consistently has become a key differentiator for manufacturers.

Battery manufacturing is a sophisticated, multi-stage process that involves the creation of battery cells, their assembly into modules and packs, and subsequent performance and safety testing. Traditionally, these tasks required extensive manual labor and were prone to variability due to human error, resulting in inconsistent quality and lower throughput.

A typical battery production process includes several critical stages:

Cell Production: The preparation and assembly of raw materials into individual battery cells, including electrode coating, drying, calendaring, and cell winding or stacking.

Module and Pack Assembly: Individual cells are grouped, connected, and integrated into modules and packs with control systems.

Testing and Quality Assurance: Each finished pack undergoes comprehensive testing for voltage, current, insulation, and capacity to ensure performance and safety standards are met.

As demand for electric vehicles, energy storage systems, and portable electronics continues to soar, manufacturers are increasingly turning to automated battery production lines to meet large-scale production needs efficiently and reliably.

Automation has become the cornerstone of modern battery manufacturing. A well-designed automatic battery production line replaces repetitive manual processes with intelligent robotic systems and digital control solutions. The benefits are numerous:

Automated systems can operate continuously with minimal downtime, significantly increasing throughput. Robotics and computer-controlled assembly minimize cycle times and ensure consistent operation across multiple production shifts. This capability allows manufacturers to meet growing global demand while maintaining delivery timelines.

One of the greatest advantages of automation is the elimination of variability. Automated inspection systems, high-precision robotic handling, and digital monitoring ensure every battery cell and module meets exacting specifications. Real-time quality tracking and data analytics make it possible to detect deviations early and maintain a uniform standard of excellence.

While the initial investment in an automated battery production line can be significant, the return on investment is realized through reduced labor costs, minimized material waste, higher yields, and less rework. Over time, the system pays for itself by delivering consistent performance with lower operational expenses.

Automation minimizes the risks associated with manual handling of potentially hazardous battery materials. Integrated safety interlocks, robotic containment, and compliance with national and international safety standards make the working environment safer and more reliable.

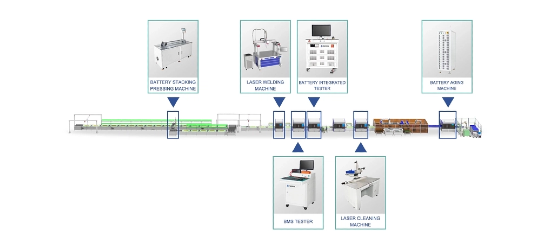

An automatic battery production line is composed of several integrated subsystems working seamlessly to ensure continuous, precise, and efficient operation.

At the heart of the automation process lies the battery pack assembly line. It is designed to integrate robotics, conveyor systems, and intelligent control software to streamline the assembly of modules into finished battery packs.

Advanced Robotics: Automated arms perform precise handling, welding, gluing, and placement of cells with micrometer-level accuracy.

Intelligent Control Systems: Programmable logic controllers (PLCs) and monitoring software continuously oversee the process, making real-time adjustments to maintain optimal efficiency.

Flexible Configuration: The assembly line can be customized for different battery pack sizes, shapes, and capacities, accommodating the diverse needs of automotive, consumer electronics, and energy storage applications.

By integrating a battery pack assembly line into production, manufacturers can achieve a higher level of automation, precision, and adaptability than ever before.

Automated cell assembly systems are engineered to meet demanding production and quality standards. The following parameters are typically essential:

Production Capacity: A throughput rate of at least 10 PPM (parts per minute) ensures scalability for large-volume manufacturing.

Quality Rate: A target of ≥99.8% excellent rate demonstrates the system’s precision and reliability.

Low Failure Rate: Maintaining a failure rate of ≤2% ensures high operational stability.

Modular Compatibility: The ability to switch between different battery types and specifications quickly allows manufacturers to remain flexible in a competitive market.

These technical requirements highlight the sophistication of modern battery cell assembly systems, which combine speed, precision, and adaptability in one integrated solution.

A well-designed production flow is the backbone of any efficient battery production line. The standard process typically includes:

Raw material preparation

Cell assembly (coating, stacking, sealing)

Module assembly and connection

Testing and formation

Final pack assembly and inspection

Manufacturers often customize this process flow to optimize yield, reduce material handling, and improve energy utilization. Advanced data systems can also monitor each stage, enabling continuous improvement through data-driven insights.

The functionality of an automatic battery production line depends on the seamless integration of various modules designed to perform specific tasks.

This station ensures the cleanliness and proper adhesion of battery components. With automatic cleaning and precision gluing functions, it eliminates contaminants that could affect performance.

Its high-speed operation—up to 12 PPM—significantly enhances production throughput while maintaining precision.

Stacking rotary tables support the alignment and layering of cells and insulating plates.

Robotic systems precisely position materials according to programmed sequences, allowing consistent stacking regardless of cell type. This flexibility is crucial for manufacturers handling multiple battery formats.

In this stage, robotic manipulators position glued cells into designated slots and perform extrusion or compression tasks for final assembly.

Manual inspection is combined with automated sensors to ensure every module meets dimensional and structural requirements.

Modern battery production lines are built with advanced safety protocols, including:

Safety fences and interlocked barriers to prevent unauthorized access.

Emergency stop mechanisms and real-time monitoring systems.

Full compliance with national and international safety regulations to guarantee a safe production environment.

These systems not only protect operators but also ensure the overall stability and reliability of production operations.

Automated equipment operates continuously and precisely, minimizing downtime and bottlenecks. Manufacturers can dramatically reduce production cycles and meet market demand with shorter lead times.

Automation ensures repeatability and consistency. Real-time data collection allows manufacturers to monitor critical parameters—temperature, pressure, voltage—throughout production, ensuring every unit meets strict quality benchmarks.

Modern battery production lines are modular and scalable. They can be easily expanded or reconfigured to produce new types of batteries, from lithium-ion to solid-state, without major infrastructure changes.

Though initial setup costs can be substantial, long-term operational savings are significant. Automation reduces waste, optimizes resource utilization, and ensures faster production cycles—all of which contribute to higher profitability.

Automated systems are more energy-efficient and produce less material waste. Combined with smart energy management software, these systems support a cleaner, greener manufacturing ecosystem—essential for companies aligned with global sustainability goals.

The automatic battery production line represents the future of energy manufacturing. By combining intelligent automation, advanced robotics, and real-time quality control, manufacturers can achieve higher efficiency, superior product consistency, and lower costs. As the world transitions toward electric mobility and renewable energy, investing in advanced battery production line technology is not just an upgrade—it’s a strategic move for long-term success.

If your company aims to elevate its battery manufacturing capabilities, now is the time to adopt an advanced automatic battery production line. Our comprehensive solutions are engineered to streamline your operations, enhance quality control, and reduce overall production costs.

Contact us today to learn how our customized automation systems can revolutionize your battery production process and keep you at the forefront of this rapidly evolving industry.