Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

As the new national standards take effect, lithium battery formation and grading equipment plays a pivotal role in ensuring the core safety of lithium batteries.

The official implementation of the Electric Bicycle Safety Technical Specification (GB 17761-2024) and two supporting battery safety standards on September 1, 2025, ushers the two-wheeler lithium battery industry into an era of “mandatory safety thresholds.” As a core component of the production chain, formation and grading equipment is reshaping the industry’s competitive landscape across three key dimensions.

Safety Performance Leap: From Passive Screening to Active Prevention

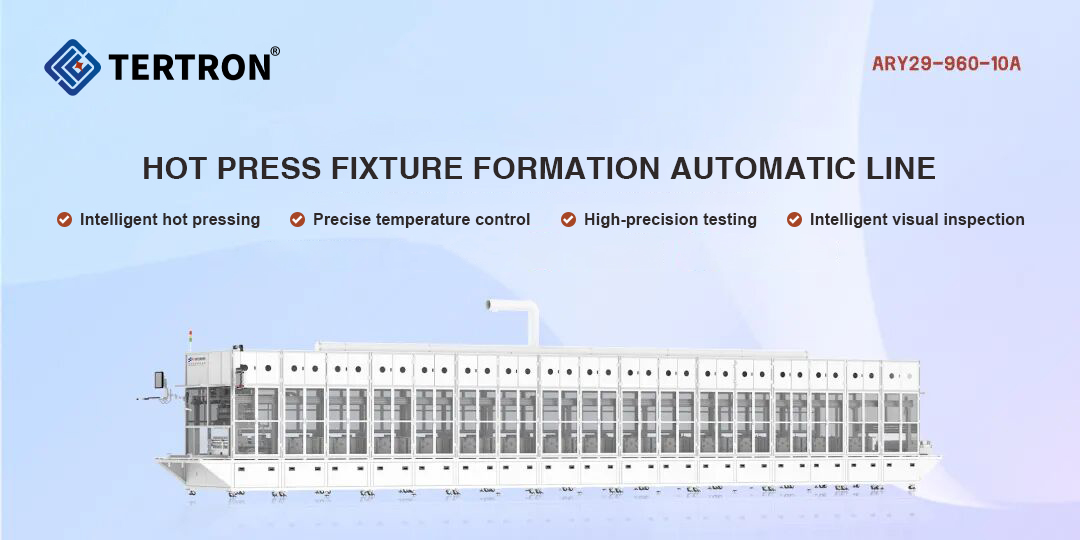

The new standards require batteries to withstand extreme tests such as nail penetration and thermal propagation, posing unprecedented challenges to cell production. Leading equipment in the industry employs high-temperature hot-press formation technology. Operating under 50–80°C and 0.1–0.5 MPa pressure, this technology accelerates electrolyte wetting, reducing SEI film formation time by 20%–40% and improving thickness uniformity by over 30%.

This process directly addresses the standards’ requirements for intrinsic battery safety: by simulating charge-discharge cycles under extreme conditions, the equipment identifies and removes potentially defective cells at the production stage, increasing the final product’s pass rate in nail penetration tests by more than 30%.

Precision Grading: EIS Technology Identifies Hidden Defects

In the grading stage, Electrochemical Impedance Spectroscopy (EIS) represents a critical technological breakthrough. The equipment applies wide-frequency AC signals (0.1 Hz to 200 kHz) to detect hidden defects such as micro-shorts and electrode misalignment, achieving a detection accuracy of 99.5%.

For example, ensuring a benchmark battery achieves its 2,500-cycle lifespan depends on the equipment’s precise tracking of the cell capacity decay curve. After 1,000 simulated cycles, premium cells with capacity retention greater than 90% are selected, guaranteeing that the final battery product continues to meet the cycle-life requirements of the new standards over long-term use.

Accelerated Technological Iteration: Intelligent Solutions for Industry Challenges

To address the new standards’ requirements for fast-charging compatibility and battery pack management, the equipment leverages dynamic parameter simulation technology. During fast-charge testing, it can replicate voltage fluctuations under 5 kW ultra-fast charging protocols and evaluate the cell’s temperature differential control when charged to 80% capacity within 20 minutes (e.g., a ΔT < 5°C for a specific battery). This capability enables manufacturers to optimize thermal management system designs, ensuring products maintain charging efficiency even in low-temperature environments down to -10°C.

For battery pack parallel management, multi-cell synchronous detection technology validates dynamic balancing capabilities when cells with different cycle histories are used together. For instance, in scenarios simulating 2–4 battery packs with varying cycle counts connected in parallel, the equipment monitors each cell’s charge-discharge curves in real time. The BMS can then apply dynamic SOP algorithms for intelligent load distribution, ensuring compliance with the new standard’s prohibition of non-compliant battery packs. Additionally, pulse formation technology reduces formation time by over 35% and internal resistance by 5%, providing essential hardware support for enhanced fast-charging performance.

Reshaping the Industry Ecosystem: Data-Driven Sustainable Development

End-to-end data traceability has become a cornerstone for compliance with the new national standards. Formation curves and grading data for each cell are recorded in real time and uploaded to the MES system, creating a unique “digital ID.” This traceability not only satisfies the requirement for unique battery pack coding but also allows manufacturers to optimize production processes using data analysis. For example, by analyzing the formation parameters of cells that failed nail penetration tests, companies can adjust charging slopes, reducing the risk of thermal runaway by over 50%.

At the cost-control level, the equipment’s intelligent sorting function classifies cells based on parameters such as capacity and internal resistance, enabling flexible battery pack configurations for different applications. Cells with capacity retention above 95% can be allocated to high-frequency usage scenarios like food delivery, while standard-grade cells suffice for everyday commuter applications. This approach ensures compliance with the new standards while improving material utilization by over 15%. Notably, the equipment’s energy recovery efficiency reaches up to 70%, potentially saving a standard production line more than 7 million RMB annually in electricity costs, achieving scalable cost reductions.

Conclusion

With the full implementation of the new national standards, the two-wheeler lithium battery industry is undergoing a strategic shift from “scale expansion” to “quality supremacy.” Lithium battery formation and grading equipment, leveraging its core advantages in enhancing safety performance, optimizing production efficiency, and enabling data-driven decision-making, has become not only a key tool for breaking through technical barriers but also a driver moving the industry towards higher safety, longer lifespan, and greater intelligence.

Under the demonstrative effect of benchmark products, intelligent equipment is empowering more companies to seize opportunities within the hundred-billion-yuan two-wheeler lithium battery market, collectively building a new, sustainable industrial ecosystem.

content is empty!