Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

With the new power bank safety regulations officially implemented on August 15, the industry is placing greater emphasis on battery pack durability, lithium-ion safety, and quality control. While consumers often focus on capacity or charging speed, the true determinants of a power bank’s long-term reliability come from two key processes in lithium battery manufacturing: lithium battery formation and capacity grading.

These two stages rely on advanced battery formation equipment and capacity grading systems, which directly influence cycle life, cell consistency, and safety performance. They are the hidden technologies behind today’s long-lasting and compliant power bank battery packs.

1. Battery Formation: The “First Charge” That Defines a Lithium Cell’s Life

Battery formation is the initial charge after electrolyte injection. During this stage, a highly critical SEI film (Solid Electrolyte Interphase) is formed on the anode surface.

The SEI layer is fundamental to battery life because it:

-Allows lithium-ion transport

-Blocks electron penetration to reduce electrolyte decomposition

-Stabilizes the electrochemical interface

-Delays capacity fading during cycling

The uniformity and density of the SEI film directly determine battery degradation rates during charge–discharge cycles.

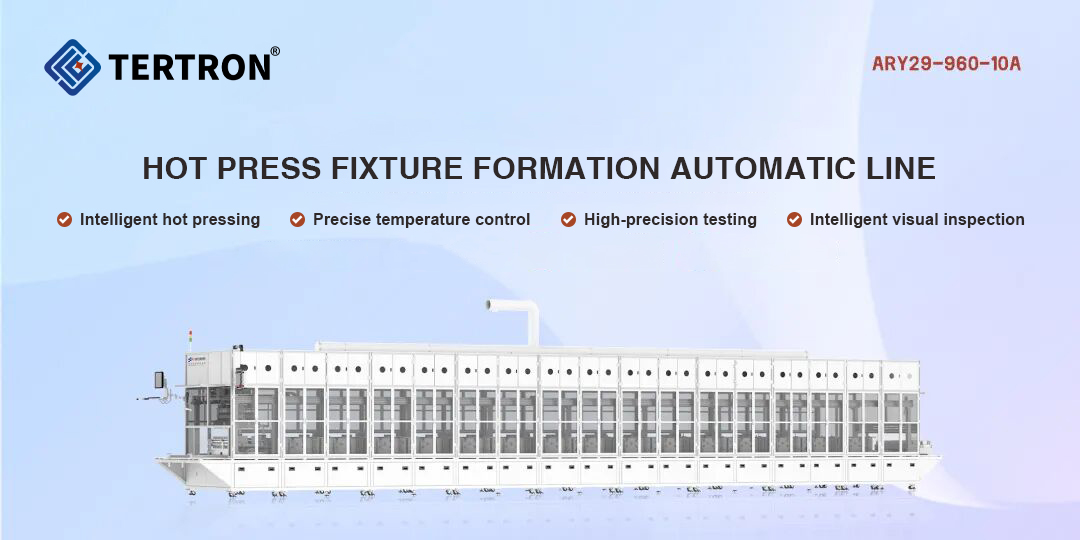

High-Temperature Hot-Press Formation: Industry Standard Under the New Regulation

Modern production lines widely adopt 50–80°C + 0.1–0.5 MPa hot-press formation. Compared with traditional ambient-temperature formation, this advanced process offers significant benefits:

-20%–40% reduction in formation time

-More uniform and denser SEI film

-10%–15% improvement in cycle life

-Higher cell consistency and stronger safety performance

This upgrade has become a key technological requirement for enhancing battery durability under the new regulatory framework.

Negative-Pressure Formation: Deep Optimization for Cylindrical Cells

For cylindrical cells such as 18650 and 21700, manufacturers adopt vacuum formation with step-current charging (0.01C → 0.2C):

-Electrolyte deeply penetrates the wound electrode structure

-Three-stage intermittent charging + rest periods balance internal stress

-Enhanced interface stability under long-cycle and high-rate conditions

This process enables cylindrical cells to maintain stable capacity retention, ensuring that power banks deliver longer effective service life.

2. Capacity Grading: The Final Performance Qualification Stage

Capacity grading is the critical procedure that measures, screens, and classifies battery cells to ensure only highly consistent cells enter battery pack assembly.

High-Precision Capacity Test System

According to T/CASMES 75-2022, capacity grading equipment must achieve:

±0.1% current accuracy

Full recording of charge/discharge curves and DC internal resistance

Automatic data logging and traceability through SQL-based systems

These parameters directly influence battery pack uniformity and long-term reliability.

Three-Step Fast Grading Process: Higher Efficiency, Higher Accuracy

Advanced manufacturing lines use a three-stage grading workflow:

Discharge → Full Charge → Discharge to 10–30% SOC

This method enables:

10%+ reduction in grading time

Rapid identification of low-capacity or defective cells through curve fitting

Long-Term Rest Evaluation: Eliminating High Self-Discharge Cells

After grading, battery cells undergo a 7–15-day room-temperature storage test. by monitoring voltage drop trends, manufacturers can filter out:

Cells with abnormal self-discharge

Cells with unstable SEI structure

Cells unsuitable for battery pack assembly

The elimination rate typically ranges from 5%–10%, ensuring high pack consistency.

3. High-Precision Formation & Grading Equipment: The Key to Battery Pack Consistency

Following the new regulation, top-tier battery manufacturers are upgrading their production lines with intelligent, automated formation systems featuring:

AI-driven thermal management algorithms

Closed-loop pressure control (±0.5 MPa) for stable SEI formation

IoT-based monitoring of voltage, temperature, and pressure

High-accuracy multi-channel charge–discharge systems

The precision and stability of these systems directly determine battery pack cycle life, safety performance, and uniformity.

4. From Factory to Consumer: The Real Value Behind the 3C Certification

The new power bank standard goes beyond simple 3C compliance—it emphasizes full lifecycle process reliability, starting from cell formation and grading.

Only cells that pass strict formation and grading validation are qualified for premium power bank applications. These cells exhibit:

Longer service life

Lower heat generation

Improved charge–discharge stability

Higher safety performance

Every durable battery pack originates from precise, controlled, and data-driven electrochemical processes, far beyond what consumers can see from the outside.

content is empty!