| Availability: | |

|---|---|

| Quantity: | |

TCS14-1024/3A

TERTRON

Industrial Battery Operated Electric Multifunctional Cylindrical Customized High Power CE Approved Capacity Grading Machine

Semi Automatic Vertical Electric Multifunctional Industrial Customized High Power Cylindrical Battery Operated Capacity Grading Machine

Description

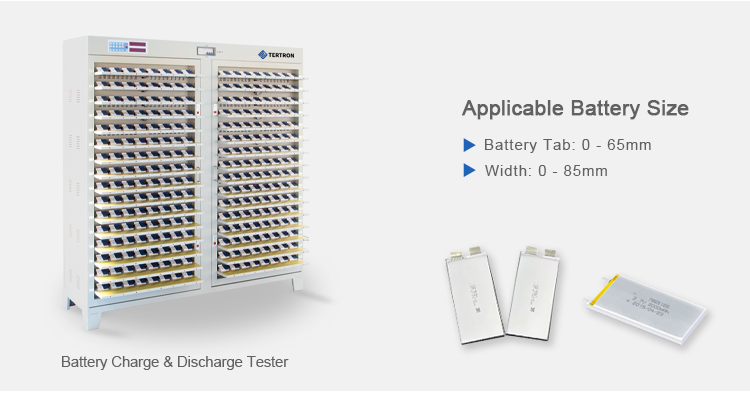

TCS14-1024/3A Traditional Linear Feedback Capacity Grading Machine is primarily used for capacity separation, capacity testing and cycle life testing of pouch cells. It is meticulously designed to meet the stringent requirements of grading soft-pack cells. Engineered for precision and efficiency, this machine sets the standard for accuracy in battery grading technology.

Key Features

- Tailored for pouch battery cell/battery pack, ensuring compatibility with various sizes and chemistries.

- Each battery test channel has an independent voltage and current loop design, which is stable and impact-free. It can realize functions such as start, stop, pause, continue and protection for a single battery channel.

- Advanced conventional linear/energy-saving capacity grading technology for accurate assessment of battery performance.

- Customizable grading parameters to accommodate specific battery chemistries and performance specifications.

- Automated sorting processes streamline operations and maximize throughput.

- High precision measurement tools provide reliable grading results in real-time.

- Comprehensive safety features ensure operator safety and prevent accidents.

- Intuitive user interface simplifies operation and monitoring for enhanced efficiency.

- Quality assurance mechanisms categorize batteries based on performance metrics, ensuring adherence to strict quality standards.

- The pallet loading and unloading method is fast and reliable; the modular design concept makes it easy to detect and maintain.

Fixture Form Pneumatic clamping /manual quick clamping |  Fixture type 28 Blue & white clasp |  Fixture spacing 60MM |  Support battery Pouch battery |  Dimensions length*width*height: 620*1900*2032(MM |

please contact us for personalized customization.

Product Parameters

| Structure Of Equipment | |||

Device Channel | 1024 channels | Overall Dimension | Width 620mm× Depth 1900mm× Height 2032mm |

| Fixture Form | 28 Blue & white clasp | Fixture Spacing | 60mm |

Support Battery Specifications | Diameter 0-20mm; length 0-60mm; Battery tab length 25-85mm (inner distance of clamp | ||

Working Power Supply | Three-phase five-wire system AC380V±10%,50HZ | ||

Working Power Consumption | ≤26 KW | Heat-Dissipating Method | Air cooling |

| Work Environment | Indoors, temperature is 10-30℃ under air convection | ||

| Channel Parameters | |||

| Voltage Measurement Range | DC 0~5V | ||

| Battery Voltage Range | Charging DC0~4.5V; discharging DC 4.5~2V | ||

| Constant Voltage Range | DC 2~4.5V | ||

| Voltage Accuracy | ± (1‰ reading + 1‰ fullness) | ||

Voltage Resolution | 0.1mV | Voltage Stability | ≤(±1mV) |

| Current Range | Charging DC 30mA~3A Discharging DC 30mA~3A | ||

| Current Accuracy | ± (1‰ reading + 1‰ fullness) | Current Resolution | ≤(±1mA) |

| Software Function | |||

Control Method | Computer controlled equipment work, whole cabinet control/single board startup/single point startup, with scanning system | ||

Communication Method | 485 serial port communication (baud rate 57600)/TCP communication | ||

Process Settings | Up to 32 steps and 256 cycles can be set | ||

Charging Mode | Constant Current, Constant Voltage, Constant Current and Constant Voltage | ||

Charging Cut-off Conditions | Voltage, current, time, capacity, -△V | ||

Discharge Mode | Constant current, constant power, constant resistance | ||

Discharge Cut-off Conditions | voltage, time, capacity | ||

Time Limit | 0~3000 minutes/work step, time unit is min | ||

Time Accuracy | ≤±1%0 | ||

Sampling Inspection Cycle | 1s-60s optional | ||

Industrial Battery Operated Electric Multifunctional Cylindrical Customized High Power CE Approved Capacity Grading Machine

Semi Automatic Vertical Electric Multifunctional Industrial Customized High Power Cylindrical Battery Operated Capacity Grading Machine

Description

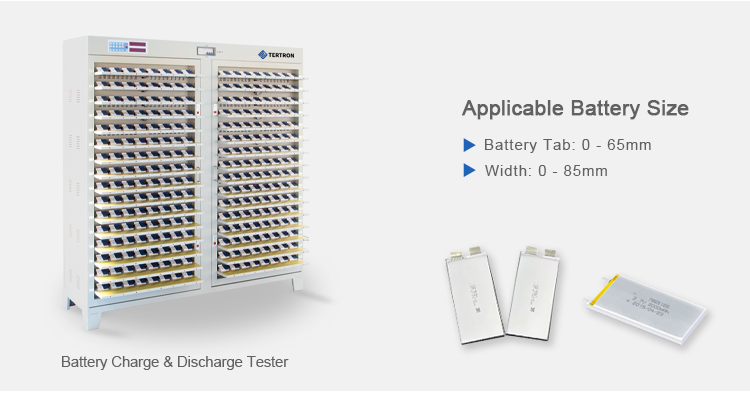

TCS14-1024/3A Traditional Linear Feedback Capacity Grading Machine is primarily used for capacity separation, capacity testing and cycle life testing of pouch cells. It is meticulously designed to meet the stringent requirements of grading soft-pack cells. Engineered for precision and efficiency, this machine sets the standard for accuracy in battery grading technology.

Key Features

- Tailored for pouch battery cell/battery pack, ensuring compatibility with various sizes and chemistries.

- Each battery test channel has an independent voltage and current loop design, which is stable and impact-free. It can realize functions such as start, stop, pause, continue and protection for a single battery channel.

- Advanced conventional linear/energy-saving capacity grading technology for accurate assessment of battery performance.

- Customizable grading parameters to accommodate specific battery chemistries and performance specifications.

- Automated sorting processes streamline operations and maximize throughput.

- High precision measurement tools provide reliable grading results in real-time.

- Comprehensive safety features ensure operator safety and prevent accidents.

- Intuitive user interface simplifies operation and monitoring for enhanced efficiency.

- Quality assurance mechanisms categorize batteries based on performance metrics, ensuring adherence to strict quality standards.

- The pallet loading and unloading method is fast and reliable; the modular design concept makes it easy to detect and maintain.

Fixture Form Pneumatic clamping /manual quick clamping |  Fixture type 28 Blue & white clasp |  Fixture spacing 60MM |  Support battery Pouch battery |  Dimensions length*width*height: 620*1900*2032(MM |

please contact us for personalized customization.

Product Parameters

| Structure Of Equipment | |||

Device Channel | 1024 channels | Overall Dimension | Width 620mm× Depth 1900mm× Height 2032mm |

| Fixture Form | 28 Blue & white clasp | Fixture Spacing | 60mm |

Support Battery Specifications | Diameter 0-20mm; length 0-60mm; Battery tab length 25-85mm (inner distance of clamp | ||

Working Power Supply | Three-phase five-wire system AC380V±10%,50HZ | ||

Working Power Consumption | ≤26 KW | Heat-Dissipating Method | Air cooling |

| Work Environment | Indoors, temperature is 10-30℃ under air convection | ||

| Channel Parameters | |||

| Voltage Measurement Range | DC 0~5V | ||

| Battery Voltage Range | Charging DC0~4.5V; discharging DC 4.5~2V | ||

| Constant Voltage Range | DC 2~4.5V | ||

| Voltage Accuracy | ± (1‰ reading + 1‰ fullness) | ||

Voltage Resolution | 0.1mV | Voltage Stability | ≤(±1mV) |

| Current Range | Charging DC 30mA~3A Discharging DC 30mA~3A | ||

| Current Accuracy | ± (1‰ reading + 1‰ fullness) | Current Resolution | ≤(±1mA) |

| Software Function | |||

Control Method | Computer controlled equipment work, whole cabinet control/single board startup/single point startup, with scanning system | ||

Communication Method | 485 serial port communication (baud rate 57600)/TCP communication | ||

Process Settings | Up to 32 steps and 256 cycles can be set | ||

Charging Mode | Constant Current, Constant Voltage, Constant Current and Constant Voltage | ||

Charging Cut-off Conditions | Voltage, current, time, capacity, -△V | ||

Discharge Mode | Constant current, constant power, constant resistance | ||

Discharge Cut-off Conditions | voltage, time, capacity | ||

Time Limit | 0~3000 minutes/work step, time unit is min | ||

Time Accuracy | ≤±1%0 | ||

Sampling Inspection Cycle | 1s-60s optional | ||